In order to map the levels of these fields, the Marcel project will focus on 2 main areas:

NEXIO and its partners win a new technological challenge: Electromagnetic field measurements on military vehicles

The antennae used on military devices produce electromagnetic waves, which are important to measure.

They can cause safety problems and disrupt nearby electronic systems.

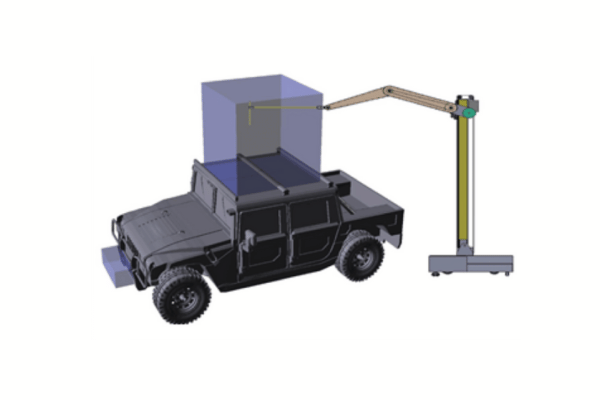

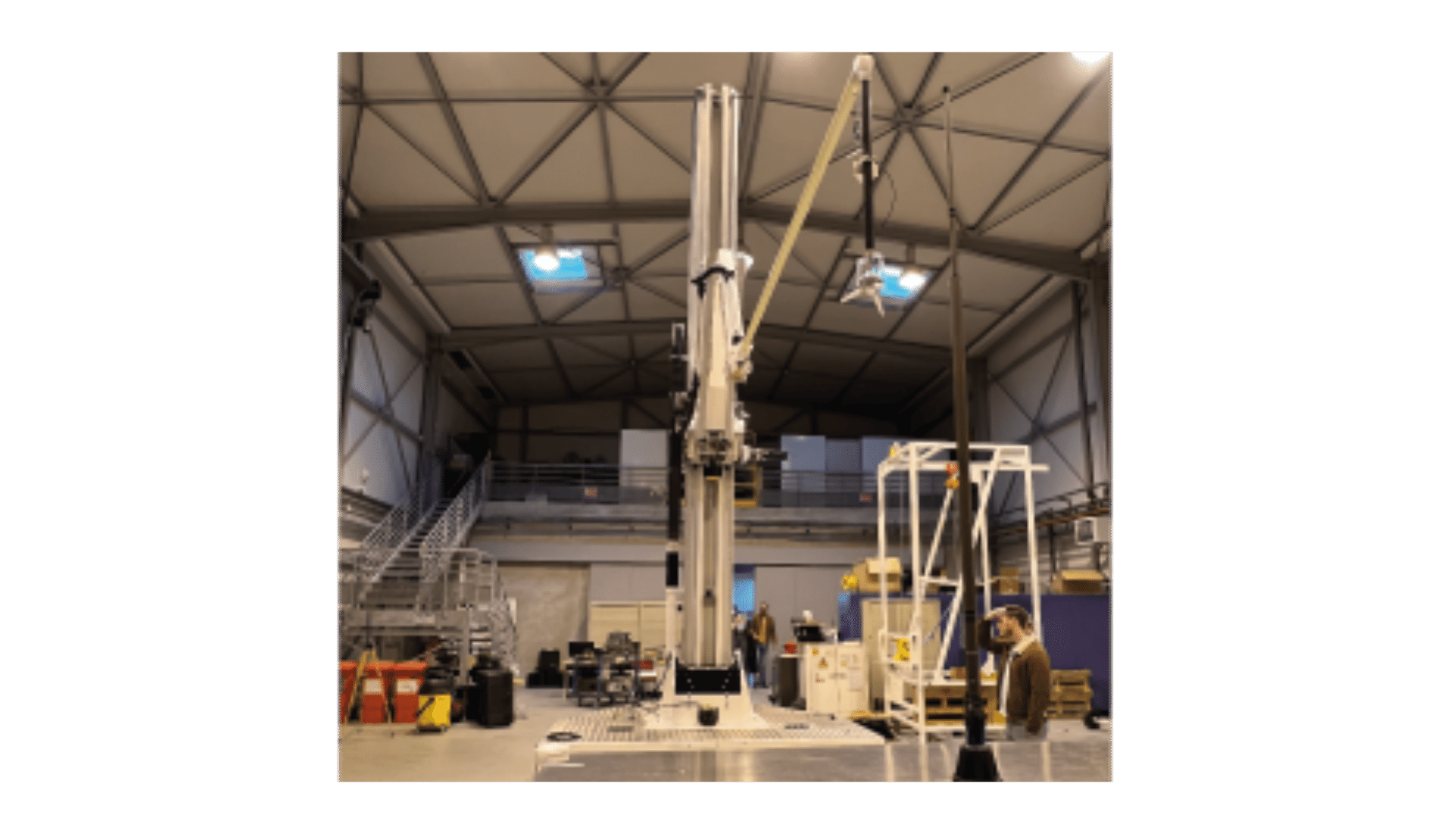

Through the MARCEL PROJECT, NEXIO and its partners Ovea Concept, SUD Projet and Spherel have developed an automated robot for measuring electromagnetic fields.

Begun in September 2019, the project was finalized in May 2022.

Electromagnetic fields are generated by the multiple signal receiving and transmitting antennas built into military vehicles.

the Marcel project has 2 main focuses

– The development of a robot (Ovea Concept, SUD Projet) to:

– move around the equipment.

– measure electromagnetic radiation using a probe.

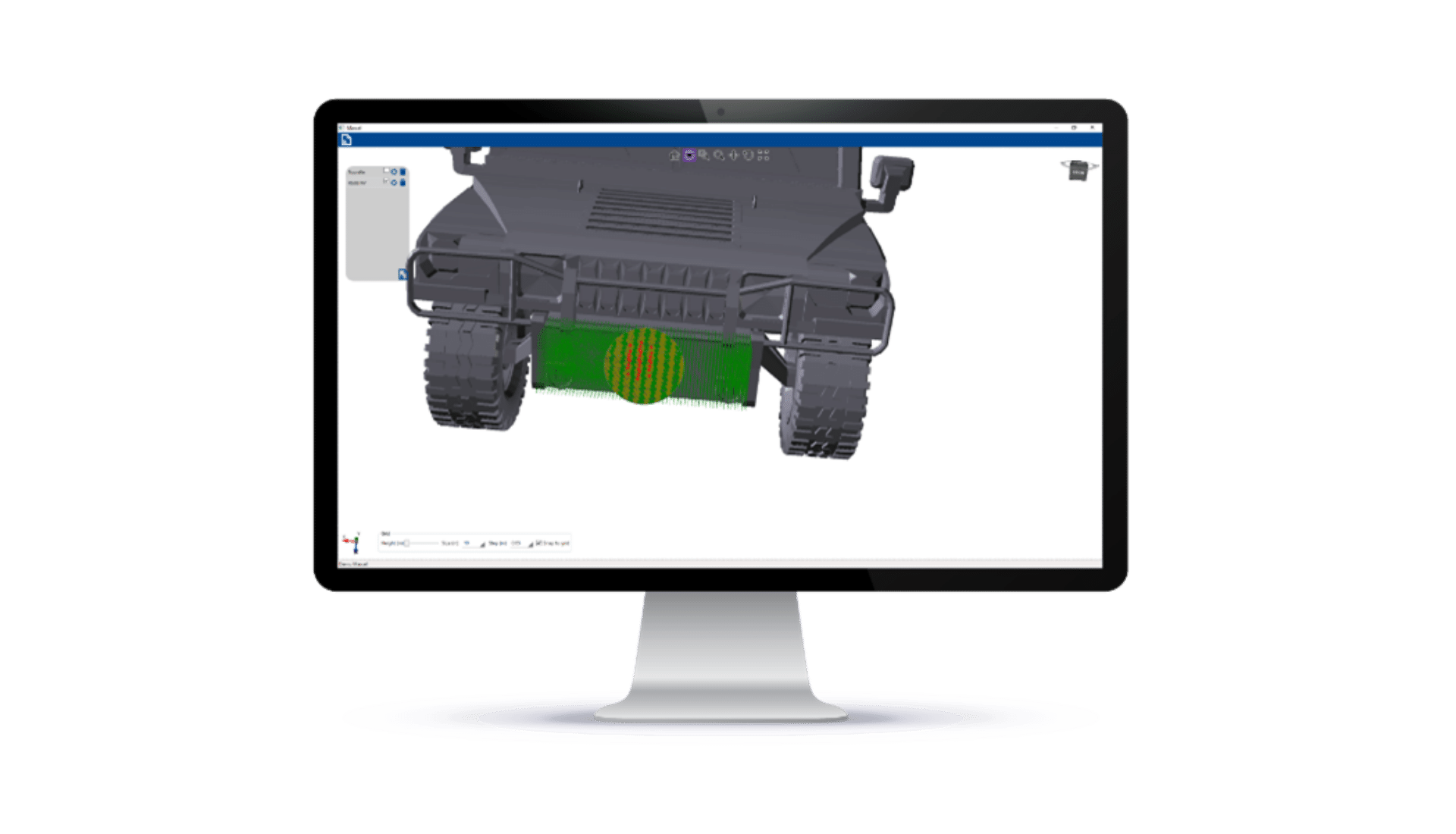

– The development of a software package (NEXIO) enabling:

– automated testing in compliance with DREP and DRAM standards

– remote control of the robot and precise selection of the various measurement zones

– 3D visualization of the results, enabling rapid pinpointing of zones below or outside the maximum authorized reference levels.

There are 2 standards established by the Ministry of the Armed Forces to control the risks associated with electromagnetic fields:

– The DREP standard: concerning electromagnetic radiation damage to people

– The DRAM standard: concerning electromagnetic radiation damage to weapons and ammunition

Spherel is in charge of overall project management.

This solution, which has now been finalized, enables all tests to be carried out remotely, without the need for manual robot movements for each measurement zone. Thanks to a single software package combining automation and control, it is possible to

It saves time during measurements, and can be adapted to other sectors, such as the automotive and space industries, depending on standards and recommendations.

About Nexio

Founded in 2003, NEXIO is a pure player in the field of waves, with the ambition of transforming them into added value for manufacturers and users.

NEXIO offers the widest range of electromagnetic products and services on the market, and has established itself as a major player in the Aeronautics, Automotive, Space, Defense and Electronics sectors.

Today, NEXIO is the largest French engineering company dedicated to electromagnetism, with a team of over 80 technicians, engineers and PhDs, capable of handling all types of EMC, Lightning, RF, HYPER and RCS test, design and simulation issues.

With a long-term vision, NEXIO is pursuing a strategy of innovation and international development.

Its flagship BAT-EMC automation software (1995) is used by industry leaders and major test laboratories.

Beyond technology and business, NEXIO men and women share values and passion.

Their ambition?

To successfully complete projects with our customers and partners, in a spirit of teamwork and mutual respect, with a focus on performance and efficiency.

About Sud Projet

SUD PROJET SARL is an industrial engineering and turnkey manufacturing company.

Founded in 1994 by Alban TRISTAN, the company’s vocation is to innovate for the benefit of manufacturers in all sectors.

EN9100 certified, SUD PROJET is a strategic player in the field of ” Aeronautical tooling “.

Equipped with high-performance industrial facilities and equipment, the company provides quality service while maintaining the necessary responsiveness to meet customer requirements.

From the development of special machines to test benches, SUD PORJET‘s successes are marked by a host of atypical achievements.

Constantly looking to the future, SUD PROJET also offers robotic integration and the creation or upgrading of production lines.

The team, made up of technicians and engineers, both in the design office and in the production trades, demonstrates unfailing agility, to bring the projects entrusted to it to a successful conclusion.

More information on https://www.sudprojet.com/

About Spherel

In an increasingly complex and fast-paced world, it is often necessary to call on a significant number of disciplines and technologies.

Spherel was born of this realization, bringing its diverse skills to its customers in a single entity.

Spherel offers a complete range of services for the development of solutions and products for the professional and consumer markets:

– definition of specifications (functional, technical and normative),

– design (electronic/electrical/computer),

– monitoring and control during the implementation phase (monitoring of subcontractors)

Spherel designs electronic devices to specifications, with embedded software (or not), with more conventional components (if required) on platforms such as Windows, Linux or Android.

Our rapid prototyping capabilities enable us to validate technical solutions very quickly.

More information on http://spherel.com/

About DGA

The DGA Techniques Aéronautiques (or DGA TA) center (formerly the Centre d’essais aéronautiques de Toulouse (or CEAT)) is a center for expertise and ground testing of aeronautical systems and equipment, belonging to the technical directorate of the Direction Générale de l’Armement (DGA/DT) of the French Ministry of the Armed Forces.

It is located in Balma, east of Toulouse.

In particular, this test center tests, for all types ofcivil and military aircraft from the Rafale to the A380:

– landing gear,

– structural strength of wings (to failure, to check safety margins),

– the impact resistance of cockpit windows, and the actual lightning resistance of aircraft in flight.

Areas of expertise also include :

– safety and reliability of critical embedded software,

– the behavior of critical aeronautical materials and structures.

– aerotransport and airdrop of equipment and personnel on French Air Force tactical transport aircraft.

– airlift of equipment and personnel on French government helicopters.

The center also plays an important role in investigations carried out as part of air accident investigations led by the BEA and BEAD, expertise which complements the analysis of “black box” recordings.

More information on https://www.defense.gouv.fr/dga

About Ovea Concept

Ovéa-concept was founded in May 2007 by two partners with extensive experience in industrial electronics and production lines.

The initial motivation was to design image processing tools combining simplicity, performance and reliability for all types of applications.

Over the years, the company has specialized in industrial vision systems for controlling electronic boards and mechanical parts, as well as machine control using vision processing.

Its strengths:

– Development of specific tabletop or on-line applications.

– Embedded application development on industrial machines.

– Consulting, training and customer support.

Its main aim is to promote image processing, with its ownµ-Vision software suite, as a truly simple and cost-effective tool.

More information at https://www.ovea-concept.com/