of users are satisfied

0

%

with a solution, a better understanding of their product, and short- and medium-term avenues for improvement.

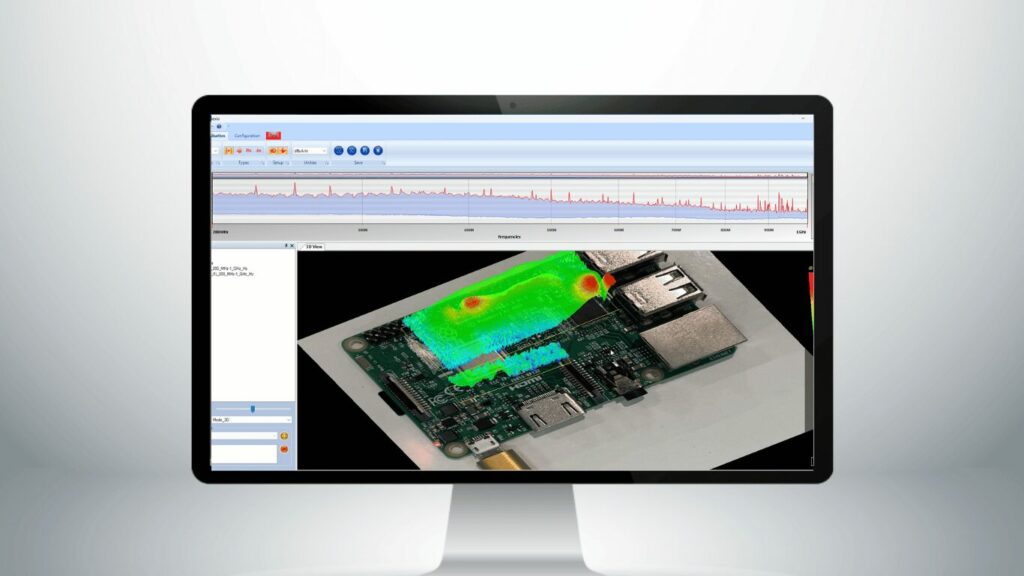

BAT-SCANNER

It helps design electronic circuits by assessing their behavior from an EMC point of view.

Locating the cause of a problem is 80% of problem solving.