Radio test laboratory

In recent years, RADIO functions have become increasingly present in electronic equipment. That's why NEXIO has teamed up with LNE to equip itself with test facilities capable of carrying out a wide range of RADIO tests to ETSI standards, as well as specific tests on request.

For more than 20 years, NEXIO has been helping small, medium-sized and large manufacturers to develop their products, with a particular focus on EMC issues and the integration of RADIO functions.

With our radio test laboratory, we provide you with reliability, expertise and innovation, ensuring uncompromising communications.

Our services Radio test laboratory

Technical characteristics of our means of transport and equipment available :

This means NEXIO can support you upstream of your qualification/certification tests to limit the risk of non-conformity/defects, thus saving you development time and limiting the risk of having to review the entire design at the end of the cycle, which is generally accompanied by a substantial increase in costs.

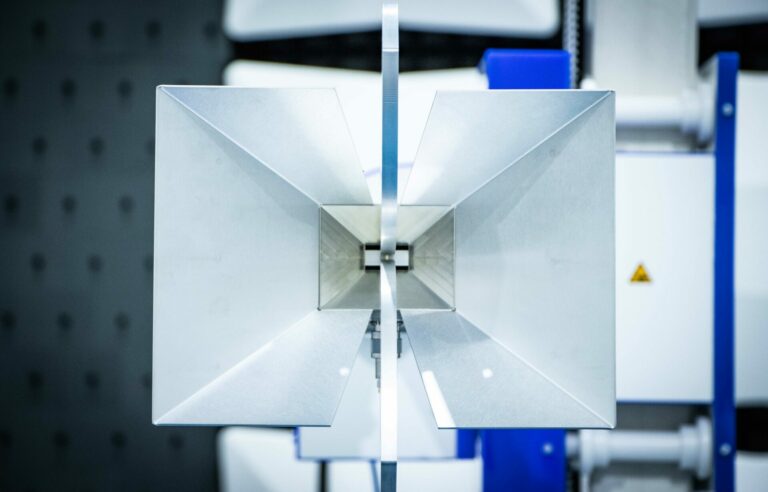

- Antenna matching

- Measuring radiation patterns

- Measuring out-of-band emissions (spurious)

- EIRP (emitting power) measurement

- Duty cycle measurement

- Measurement of occupied bandwidth

- Measurement Receiver sensitivity

- Blocking tests

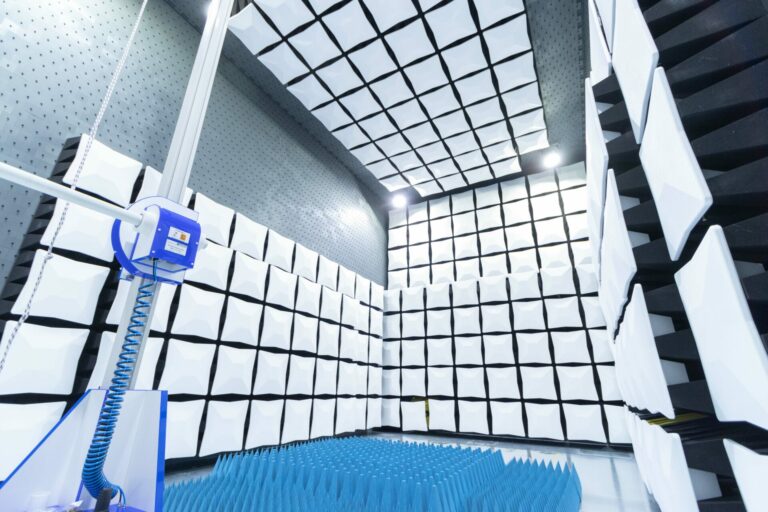

- Frequency range for radiated testing 30MHz-40GHz

- Turntable supporting up to 1T

- Height-adjustable mast 1 to 4m

- Maximum measuring distance 3m

- Room dimensions (9*5.5*7)

- 2G/3G/4G/5G network simulator

- 1Hz-44GHz measurement receiver

- Variable attenuator

- Vector signal generator

6 Reasons to Choose Nexio for Your Radio Test Needs

Risk reduction

By carrying out radio tests before bringing a product to market, you can identify and correct any compliance or interoperability problems, reducing the risk of legal disputes, financial losses and reputational damage.

Advanced test automation

Automatic configuration of ETSI tests according to frequencies and communication technologies, with CMX and CMW control for standard protocols (2G to 5G, and LTE-M / nb-IOT)

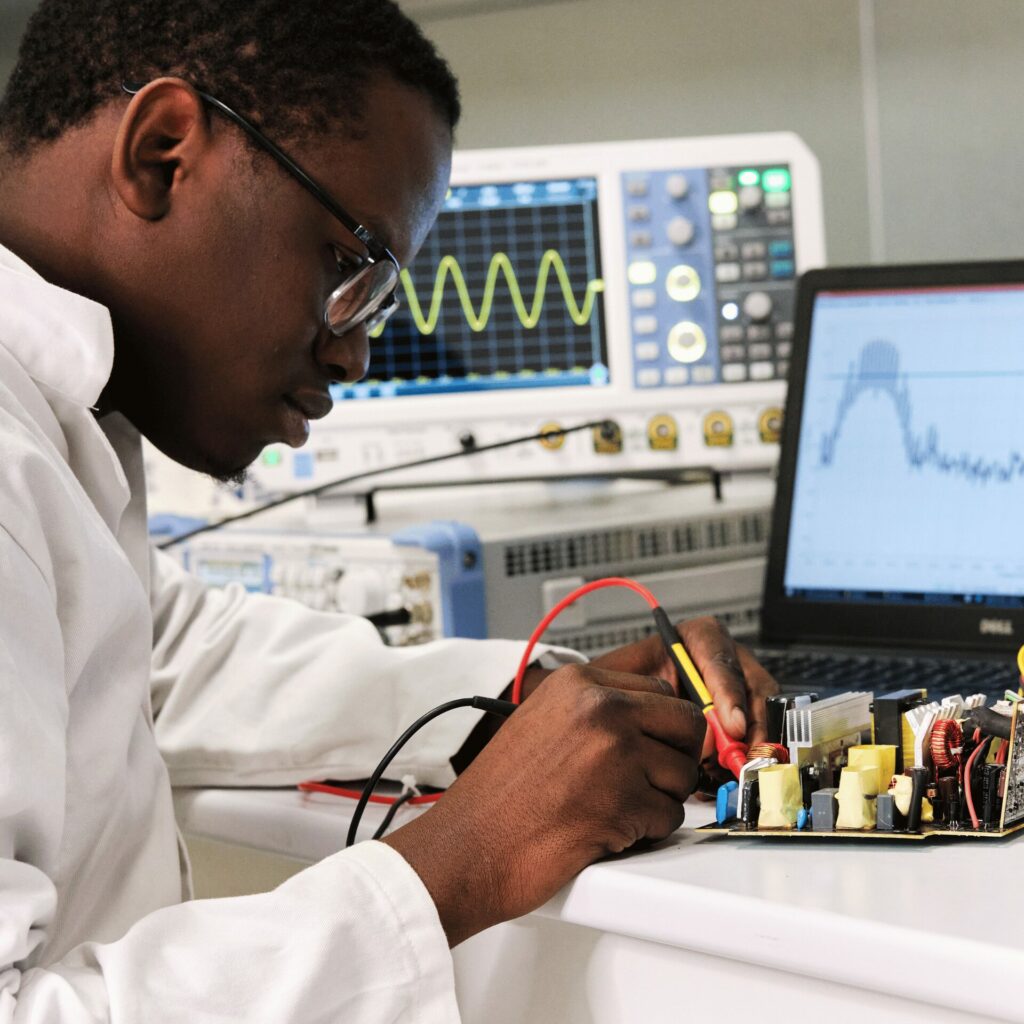

Access to an experienced and specialized team

The men and women at Nexio are technicians, engineers and doctors, all with significant experience in the field of electromagnetism, to guarantee you a quality service.

Cost savings

Our customers only pay for the tests and services they need.

A complete range of tests

Our laboratory offers a wide range of testing services. This enables us to adapt to every customer requirement.

Access to state-of-the-art equipment

Our radiofrequency laboratory is equipped with state-of-the-art, calibrated test equipment. This guarantees accurate and reliable results.

To provide high-quality radio frequency services, Nexio has set up a GIE (Groupement d'Intérêt Economique) with LNE.

LNE supports manufacturers, institutions and local authorities in their safety, health, environmental impact, performance, reliability and competitiveness issues, through its 5 business lines: measurement and metrology, research, testing and expertise, certification and training.

It is a privileged, independent and recognized technical partner.

LNE is at the forefront of French metrology, with a number of leading multi-technical platforms at national and international level. These are the fruit of advanced R&D in measurement and testing, and bring together cutting-edge human and technical resources.

It is also a group of 1,000 employees, located in France and around the world, close to its customers and their ecosystems.

Thanks to its specialized subsidiaries, it supports them in conquering new markets and controlling their subcontracting.

Thanks to this collaboration, we are merging our measurement equipment with that of LNE to create a radiofrequency test platform featuring state-of-the-art equipment, including a 5G band simulator.

This synergy enables us to offer our customers comprehensive, specialized support.

Frequently asked questions

The first crucial step is to determine the causes of these non-conformities.

Depending on the situation, several approaches are possible.

In some cases, it may be necessary to use a near-field scanner to analyze the sources and propagation paths of the frequencies causing the problems.

The second step is to find the most appropriate solutions to the problems encountered, while maintaining the expected wireless performance.

The main causes are unintentional radiation (Spurious) and equivalent isotropic radiated power (EIRP) tests.

To avoid non-compliance with these tests, we strongly recommend you carry out pre-qualification tests, which will enable you to assess your system’s radio performance while complying with the requirements of radio standards.

- Risk analysis is an essential process for identifying, assessing and managing uncertainties that could lead to non-conformance or problems at various stages of product development, particularly during the design phase.

When carried out as early as the design phases, such as schematic design (the creation of the electronic schematic) and routing (the design of the printed circuit board), it enables risks to be anticipated and prevented. - This means that design teams can take proactive steps to avoid costly non-conformities.

For example, they can modify the design, choose more appropriate components, or implement specific design practices to minimize risk.

This can lead to significant budget savings by reducing the need for costly corrections after manufacture or during subsequent testing and validation phases.

In short, early risk analysis in the design process helps to prevent non-conformities, improve product quality and, ultimately, save budgets by avoiding costly rework at advanced stages of development.

Resolving complex non-conformities in radio testing may require additional resources, including specialized technical expertise (hardware and software), and advanced test equipment such as a near-field scanner.

A methodical approach and close collaboration with radio compliance experts can be essential to overcoming these challenges.

Integrating a certified radio module can simplify the certification process for your product, but you’ll still need to ensure that the module is used in accordance with certification requirements, carry out tests and provide the necessary documentation to demonstrate compliance of the entire product.